Bazar-Linear bearing box sliding block is a linear guide element used in industrial machinery and equipment. It consists of a box slider and a linear bearing. The box slider has a movable linear bearing kit inside that slides up and down along the axis.

Box sliders are usually made of aluminum alloy or steel, with high strength and corrosion resistance, and can be used in a variety of harsh working environments. Linear bearing box sliding block has the advantages of simple structure, easy installation and maintenance, and is widely used in machine tools, automatic production lines, conveying equipment and other mechanical fields.

The inner surface of the box sliding block is usually equipped with linear bearings, and the outer surface of the box is provided with mounting holes, which can be used to fix the sliding block. Linear bearings can withstand the force along the axis, so that the box slider can slide smoothly along the axis. The sliding surface of the box sliding block is usually treated with special technology, which has excellent wear resistance and corrosion resistance, and can meet various high precision linear guiding needs.

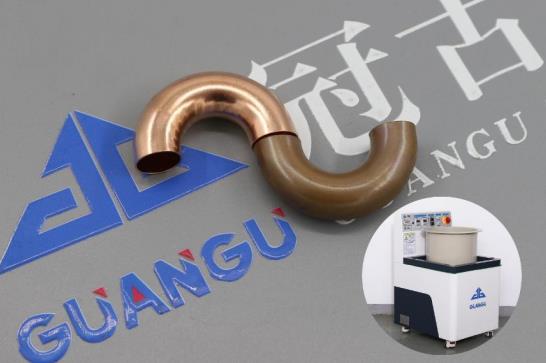

The linear bearing box sliding block is deburred by magnetic polishing machine

Linear bearing box sliding block is a linear guide element of mechanical equipment, which usually needs to be precision machined and polished to ensure its surface smoothness and dimensional accuracy to meet the requirements of high precision linear guide.

Magnetic polishing machine is a kind of mechanical equipment for surface treatment and polishing, it uses the role of magnetic force and magnetic abrasive, in the grinding and polishing process to remove burrs, poor finish and other surface defects, so as to achieve the effect of improving the surface quality.

Therefore, if there is burr on the surface of the linear bearing box sliding block, the magnetic polishing machine can be considered for deburring treatment. When using magnetic polishing machine for deburring, attention should be paid to selecting appropriate magnetic abrasive and reasonably controlling processing parameters to avoid unnecessary damage to the surface of linear bearing box sliding block. In addition, in order to ensure the quality and precision of the polished surface, it is necessary to carry out the corresponding cleaning and testing work.

Wechat

Wechat